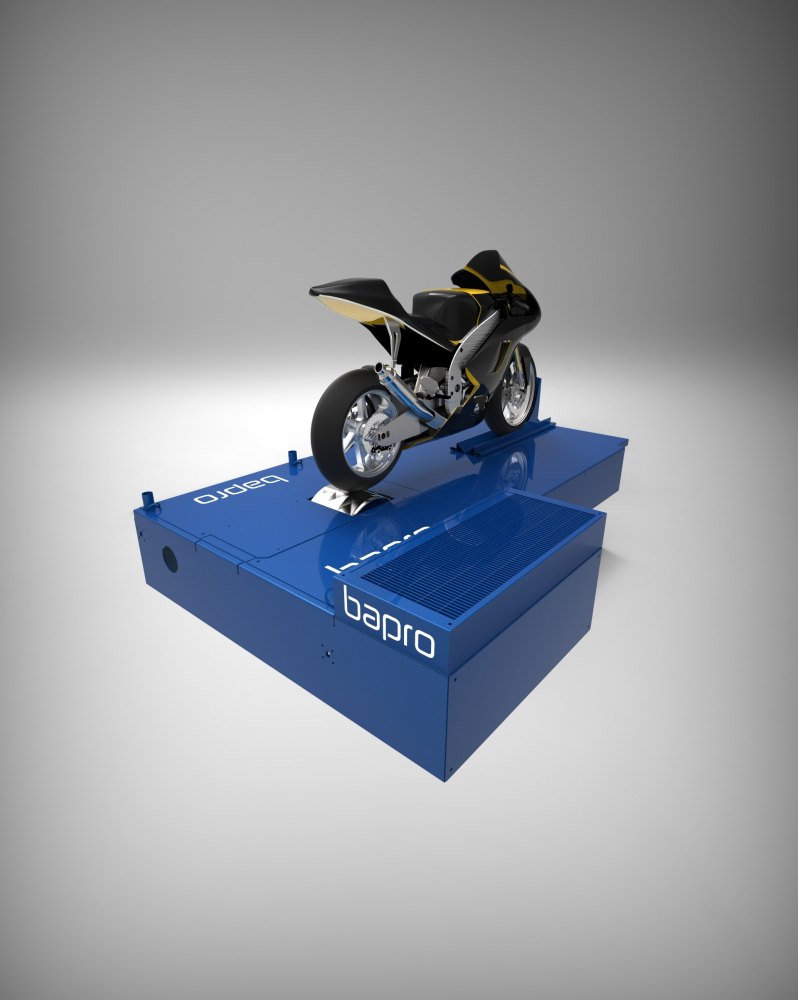

La série S est fournie avec des rouleaux godronnés par enlèvement (double passage entrecroisé), frein à courant parasite, cellule de charge et seulement des composants de haute qualité ; afin de garantir la précision et la flexibilité typiques des Bancs d’Essai de Puissance Bapro. La série S (Standard) a été conçue pour tous les ateliers qui souhaitent mettre en œuvre les services de diagnostic, de révision, Tuning et chip Tuning pour puissances moyennes / faibles. Comme tous nos produits, le choix des composants et les normes de qualité les plus élevées, garantissent la quasi absence d’entretien et une fiabilité maximale dans le temps. Tous nos Bancs avec un rouleau peuvent ensuite être transformés en modèles avec le deuxième rouleau.

✔️ Utilisé par les constructeurs de véhicules électriques

Mechanical features:

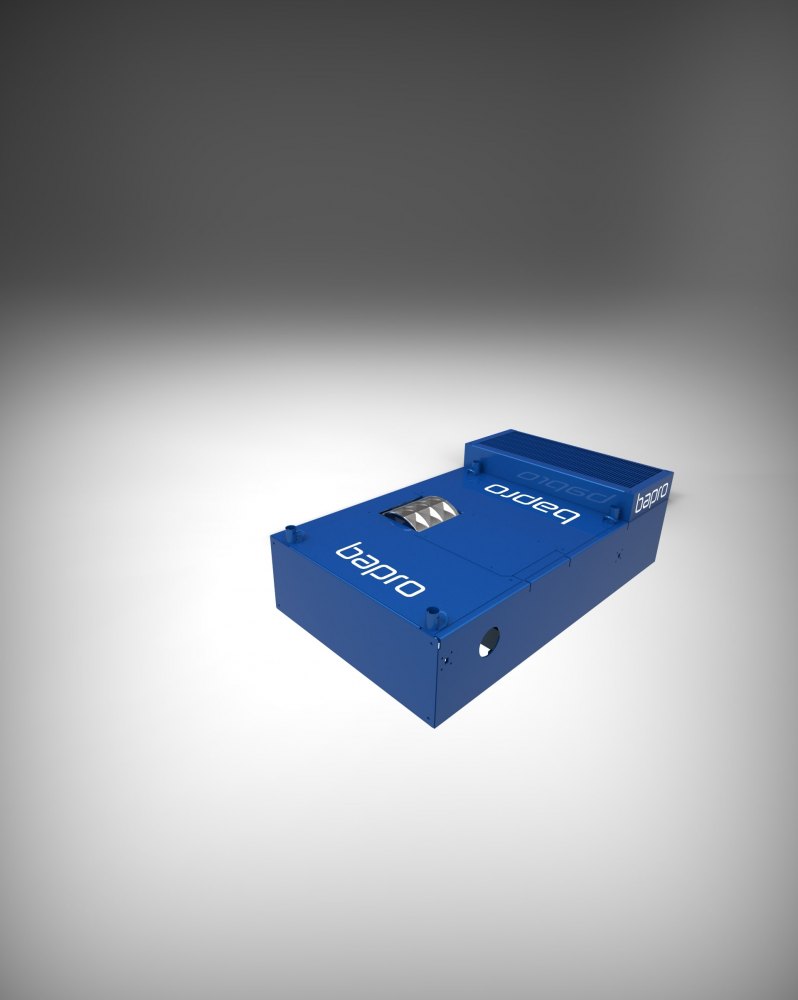

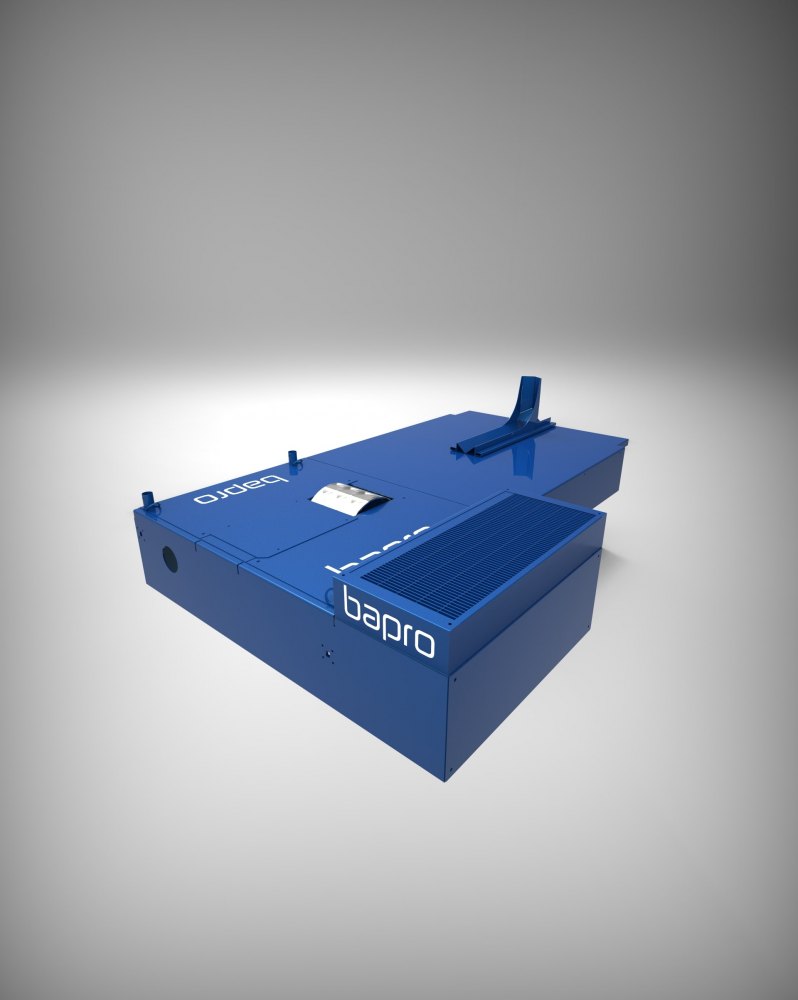

- Roller diameter: 400 mm

- Roller width: 310 mm

- Qualité d'équilibrage G 2.5

- Dimensions 3360×1860 mm

Performance:

- Maximum speed 330 km/h

- Maximum adsorbable power 450 HP

- Maximum measurable power 500 HP

- Maximum traction force 5000 N

Power supply:

- voltage 3/N/PE 400 VAC

- frequency 50 Hz

- fuses 16 A

Advantages:

- Shorter repair time (fast and exact diagnosis)

- effective use of the instruments already present in workshop (diagnosis equipment, gas analyzer)

- Avoid any risks from road tests (traffic, accidents, fines)

- Results certification (performance enhancement)

- Accessories sale improvement by result verification (exhaust systems, efi controller etc..)

- Second-hand vehicles sale improvement by engine health certification

- Vehicle check before second-hand trades

- Renting for tests and technical checks

Measuring program:

- Trasmission verification (clutch slippage)

- Power step test

- Power sweep test

- Cooling system check (radiator, fan sensor, thermostatic valve)

- Diagnosis by gas analyzer under load

- Vehicle test with constant speed

- Vehicle test with constant force

- Vehicle test with constant load

- Road simulation (slope, drag resistance, weight)

- Vehicle test with constant RPM

- Durability tests

- Engine mapping to all RPM

- Diagnosis by scantool during road simulation

- 1 eddy current brake, 1 big diameter roller, knurled over the entire width, finished by CNC cut knurling

- Lambda Input allows to connect a lambda probe with an external controller

- Fully functional management software

- Safety Equipments: Side safety barriers with logo, Anchoring ratchet straps, High attenuation ear muff

- Single Ventilation system movable on wheels, 3 kW, flow rate 22.000 m3/h with remote control

- Proportional ventilation speed control adjust the fan speed in function of the roller speed

- Wide band lambda system 5 wires wide band lambda probe with controller

- Front wheel adjustable mechanical lock with or without front frame

- Integrated Tiltable ramp made by grating with gas springs

- Personal computer and display

- PC trolley on wheels

- Removable aluminium alloy loading ramp

- Infrared remote control

- Boost pressure input

- Air Conveyor

- OBDII parameters reading and dtcs deleting without the need for additional hardware and dedicated interfaces.

| BPM-1R S | BPM-2R HP | ||||||

| Performance | |||||||

| Maximum speed | 330 km/h | 350 km/h | |||||

| Maximum adsorbable power | 450 HP | 500 HP | |||||

| Maximum measurable power | 500 HP | 550 HP | |||||

| Maximum traction force | 5000 N | 5000 N | |||||

| Mechanical features | |||||||

| Rollers diameter | 400 mm | 400 mm | |||||

| Rollers width | 310 mm | 310 mm | |||||

| Roller balancing grade | G 2.5 | G 2.5 | |||||

| Equivalent base inertia | 80 Kg | 80 Kg | |||||

| Dimensions | 2560×1860 mm | 2560×1860 mm | |||||

| Deck height | 410 mm | 410 mm | |||||

| Weight | 500 kg | 500 kg | |||||

| Voltage | 400 V 50 Hz 3/N/PE | 400 V 50 Hz 3/N/PE | |||||